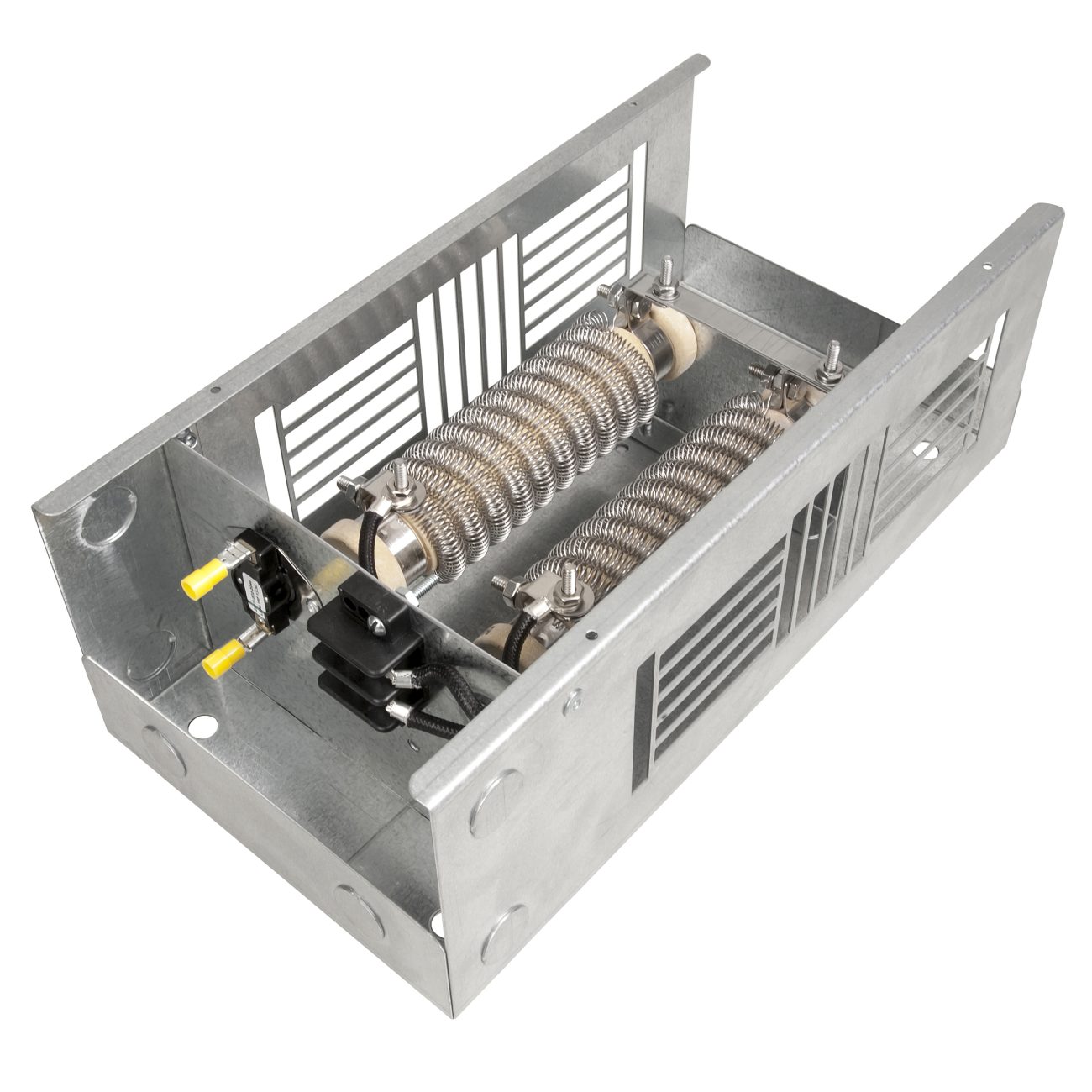

Resistor Elements

When overhead cranes are used in industrial facilities, crane resistor banks are frequently used for control of hoisting and lowering speeds, as well as positioning the crane itself. Resistors are usually mounted in, or on top of, the bridge structure.Many steel mills use DC motors because, in the past, DC power was the best way to hoist heavy loads. Newer plants are increasingly utilizing more readily available three-phase power, and wound rotor motors are often employed.Brake resistor control techniques — In hoisting and lowering operations, some special considerations are involved. Hoisting is straightforward — the load is resisting the motor, and positive torque against gravity is required. In lowering an empty hook, it may be necessary to drive the hook down, since gravity may be insufficient to lower it at the desired speed. 24 hour turnaround on crane motor control resistors‘ quotes.

But, when the hook is loaded, the load may tend to overhaul the motor, which then may have to apply a retarding torque as if it were hoisting. Dynamic braking ensures the load won’t run away and crash instead of making a soft landing.

All of these conditions require modifications of the speed-torque curve of the hoist motor. This is readily achieved by

applying the proper amount of external armature and field resistance.

A resistor bank is the practical device available for the purpose. Operators effect changes in motor speed with various loads and operate a bank of magnetic contactors to achieve the desired operation. The contactors change taps on the resistor banks as required to maintain appropriate rotor circuit resistance.

Post Glover’s stainless steel grid resistors are an excellent choice for heavy industrial applications because of their durability and dependability in severe environments.

Initial information needed for sizing your resistor:

- Application

- Horsepower

- Line voltage

- Full load amps

- Starting torque

- Number of speeds

- Duty/NEMA class (see tables)

- For dynamic lowering applications, include manufacturer of control package.